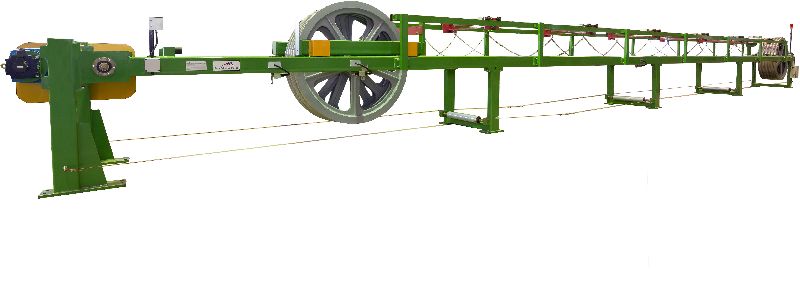

Drycure CCV Lines for MV/HV/EHV

Description: Royle Systems Group Partnered with Anaconda Cables to develop Dry cure CCV technology and were the first to patent the same. With over 100s of CCVs running all over the world Royle has been pioneer in this Industry. Royle manufactured Catenary Continuous Vulcanization (CCV) systems designed for the production of XLPE insulated power cables up to 132kV. Royle is the only manufacturer in India capable of manufacturing the Catenary Tubes in-house. This advanced cable production line efficiently performs a triple extrusion process, precisely applying the inner semiconductor layer, insulation layer, and outer semiconductor layer in a single pass.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

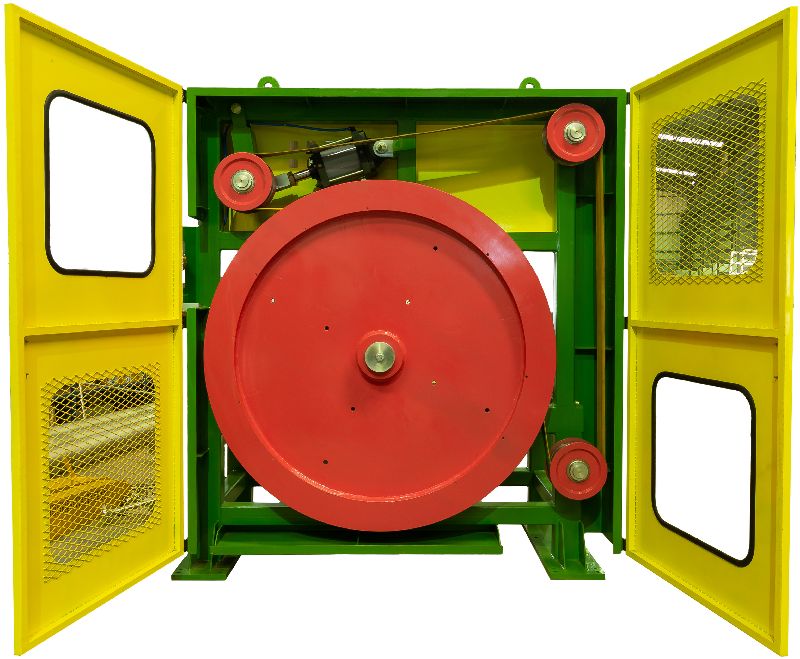

| Pay-off: | 2600 to 3600mm |

| Accumulators: | 1200mm to 2100mm |

| Metering Capstan | 1500mm, 1800mm, 2000mm and 2500mm |

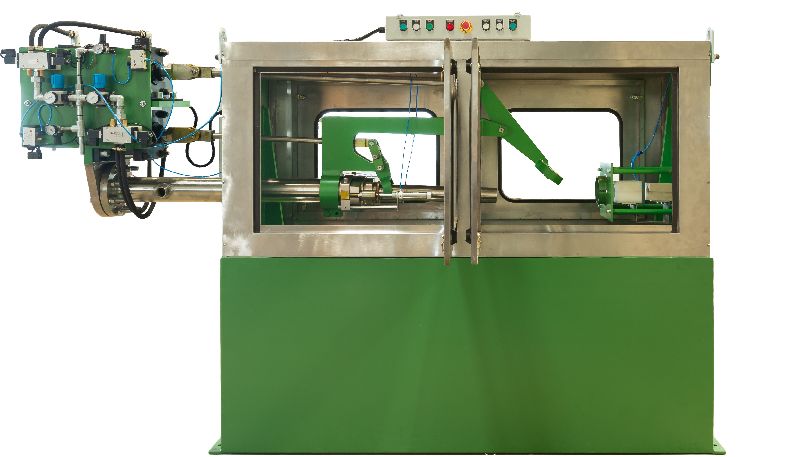

| Extruder Combinations | 65mm/120mm/65mm, 65mm/150mm/80mm, 80mm/200mm/100mm |

| Splice Box | 150mm, 200mm, 250mm |

| Curing Zone | 6 to 9 nos. based on line speed requirement and space availability. |

| Cooling Zone | 10nos and More Based On Cooling Requirement and Space Availability. |

| Pullout Capstan: | 1500mm, 1800mm, 2000mm and 2500mm |

| End Seal: | 100mm and 150mm |

| Helping Caterpillar: | 1200mm and 1500mm. |

| Take up | 2600 to 3600mm |

Description: Royle Systems Group Partnered with Anaconda Cables to develop Dry cure CCV technology and were the first to patent the same. With over 100s of CCVs running all over the world Royle has been pioneer in this Industry. Royle manufactured Catenary Continuous Vulcanization (CCV) systems designed for the production of XLPE insulated power cables up to 132kV. Royle is the only manufacturer in India capable of manufacturing the Catenary Tubes in-house. This advanced cable production line efficiently performs a triple extrusion process, precisely applying the inner semiconductor layer, insulation layer, and outer semiconductor layer in a single pass..